AI

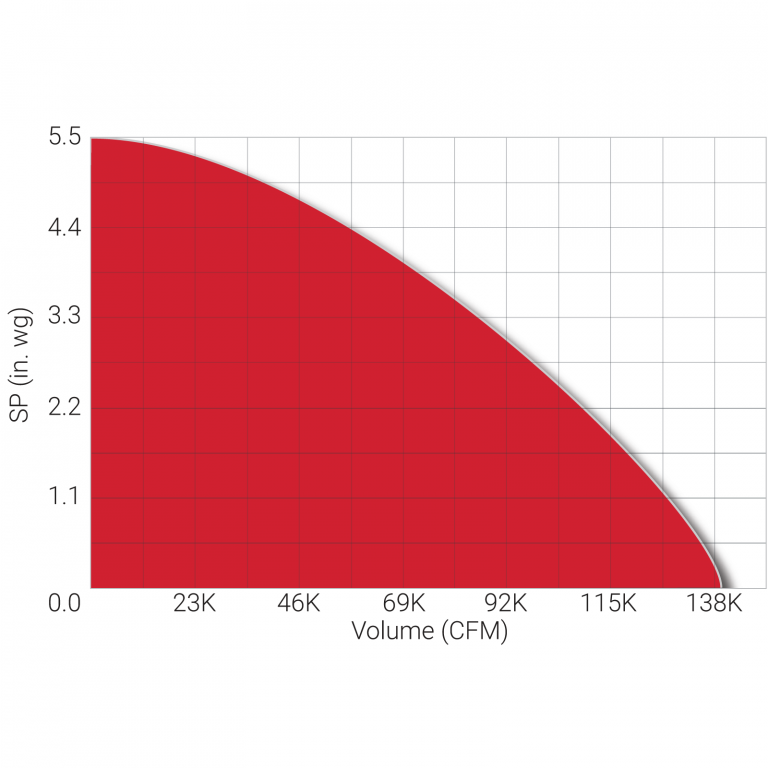

High Efficiency Tubeaxial Fan

Highly efficient cast aluminum propeller axial, in-line. Direct drive, duct mounted. Propeller is available in a multiple number of blade and hub combinations along with pitch combinations. Commonly used to supply or exhaust air in areas where space is at a premium, like parking garages, stairwell or other tight spaces. Unit can be provided with a vane section or reversible prop. Available with optional UL Smoke Control Listing.

Features

- Fully welded housing

- Pre-punched flange for duct connection

- Lifting lugs

- Mounting brackets welded to the housing

- Propeller installed with taper lock bushing

Construction

- Housing Material: Steel

- Finish: Lorenized ™

- Ventilator Type: Fan

- Impeller: Axial

Configuration

- Mounting: Roof (Curb Mount), Roof (Rail Mount), Ceiling/Suspended, Duct Mounted/Inline, Wall, Floor

- Drive Type: Direct Drive

- Motor: AC, PM

- Max Operating Temp (Standard Construction): 105°F

- Speed Control: VFD, Vari-Flow, SimpliDrive

- Flow: Supply, Exhaust, Reversible

- Filtration: Unfiltered

AI

Propeller axial, in-line, direct drive, duct mount

Recommended Products

Accessories & Vari-Flow Controls