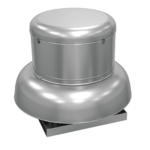

FCE

Roof Mounted Downblast Fiberglass Reinforced Plastic FRP Centrifugal Exhaust Fan

FRP (Fiber reinforced plastic) centrifugal roof exhauster. Downblast, belt or direct drive, curb mount. Commonly used in water treatment plants and other corrosive environments where traditional coated units are not suitable.

Features

- FRP wheel molded and formed as one solid piece

- Lifting lugs

- Cast regreasable bearings (Belt Drive)

- One piece molded curb cap with sealed corners

Construction

- Housing Material: Fiberglass

- Ventilator Type: Fan

- Impeller: Centrifugal

- Bearings: L-50, over 200,000 hours

Configuration

- Mounting: Roof (Curb Mount)

- Drive Type: Direct Drive, Belt Drive

- Motor: AC

- Max Operating Temp (Standard Construction): 180°F

- Flow: Exhaust

FCE

Centrifugal exhaust, downblast, belt or direct drive, curb mount

Recommended Products

Accessories & Vari-Flow Controls