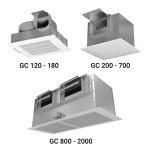

DB

Duct Blower - Forward Curved

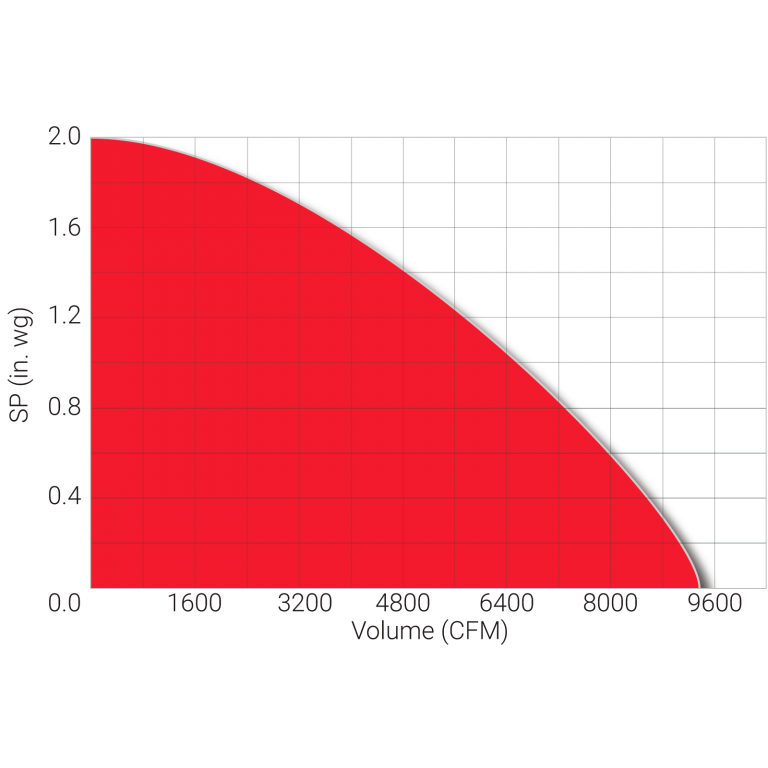

Centrifugal, in-line fan with a double-width, double-inlet forward curved blower inside the housing. Belt drive, duct (square) mount. Used in a variety of commercial applications where the air is ducted through the building. An economical choice for low speed, low pressure general ventilation application. Motor is installed within the unit for a more compact design.

Features

- Multiple access doors for service

- Slip-fit duct connection

- Factory installed horizontal mounting brackets

- Motor mounting inside the housing for compact design

Construction

- Housing Material: Galvanized Steel

- Finish: Mill

- Ventilator Type: Fan

- Impeller: Centrifugal

- Bearings: L-50, over 200,000 hours

Configuration

- Mounting: Ceiling/Suspended, Duct Mounted/Inline

- Drive Type: Belt Drive

- Motor: AC

- Max Operating Temp (Standard Construction): 105°F

- Speed Control: VFD, Vari-Flow, SimpliDrive

- Flow: Supply, Exhaust

- Filtration: Unfiltered

DB

Centrifugal, in-line, belt drive, forward curved, duct (square) mount

Recommended Products

Accessories & Vari-Flow Controls