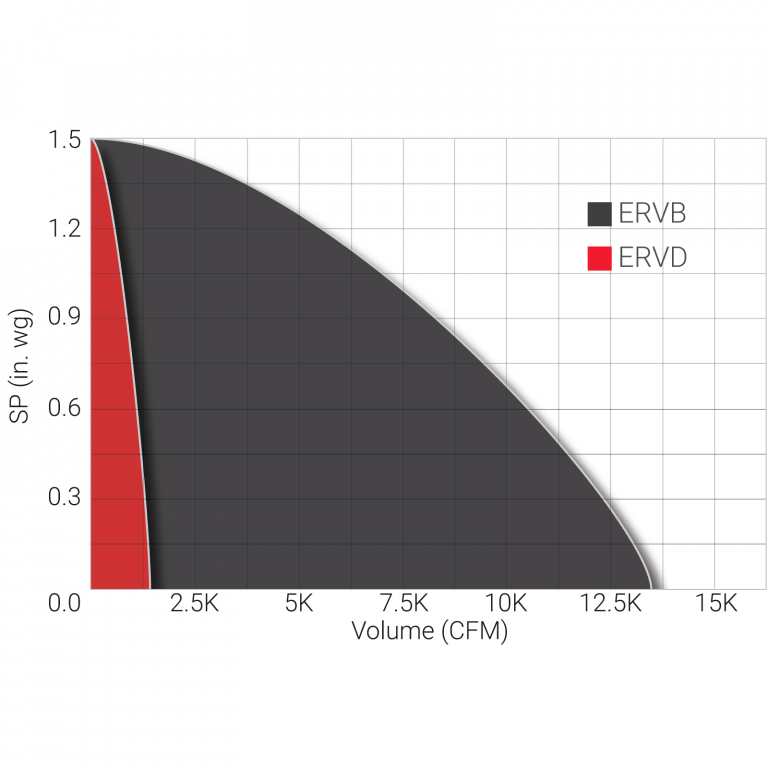

ERV

Energy Recovery Ventilator - Rotary Wheel Heat Exchanger

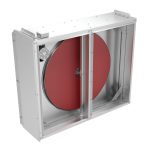

Energy Recovery Ventilator available in either belt or direct drive, with a desiccant impregnated rotary wheel. The rotary energy wheel is available in either total energy recovery (sensible and latent) or sensible only energy recovery. Rotary wheels have higher effectiveness than compared to other energy exchange medias. The unit is a complete ventilator with internal blowers for both the supply and return air.

Features

- Molecular sieve desiccant total energy rotary wheel

- Energy wheel slides out for inspection and cleaning

- Large access doors

- MERV 8 pre-filters for both airstreams

- Lifting lugs

- Single point electrical connection

- Tempered air options

- DX cooling

- Chilled water

- Hot water

- Electric post and preheat

- Indirect gas

Construction

- Housing Material: Galvanized Steel

- Finish: Mill

- Ventilator Type: ERV

- Impeller: Centrifugal

Configuration

- Mounting: Roof (Curb Mount), Ceiling/Suspended, Duct Mounted/Inline

- Drive Type: Direct Drive, Belt Drive

- Motor: AC, EC

- Speed Control: FSC, VFD

ERV

Energy Recovery Ventilator, belt or direct drive, rotary wheel

Recommended Products

Accessories & Vari-Flow Controls