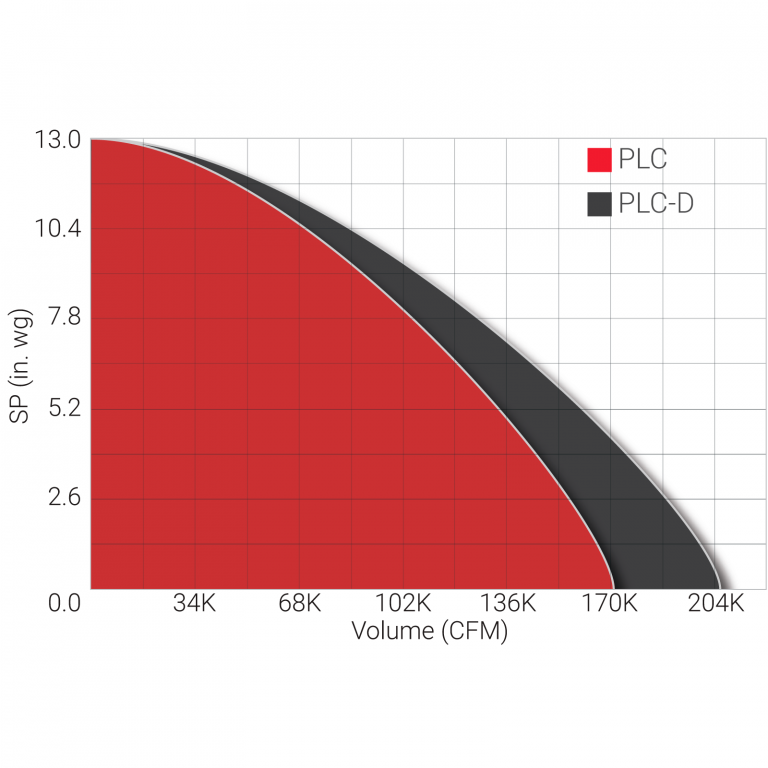

PLC

Centrifugal Plenum Blower

Centrifugal plenum blower with airfoil wheel. Flexible design, available in several AMCA arrangements, belt or direct drive, to meet design requirements. All arrangements feature a fully welded housing and wheel. Typically installed in air handling plenums and air handling units.

Features

- Fully welded steel airfoil wheel

- Available in 9 and 12 blades wheel design

- Full welded housing

- Available in arrangement 1, 3, 3S, 3T & 3V (Belt drive)

- Available in arrangement 4 (Direct drive)

- Class I, II, & III

- Lifting lugs

- Cast regreasable bearings (Belt Drive)

Construction

- Housing Material: Steel

- Finish: Lorenized ™

- Ventilator Type: Blowers/Utility Sets

- Impeller: Centrifugal

- Bearings: L-50, over 200,000 hours

Configuration

- Mounting: Floor

- Drive Type: Direct Drive, Belt Drive

- Motor: AC

- Class: 1, 2, 3

- Arrangements: 3, 4

- Rotatable Housing: No

- Max Operating Temp (Standard Construction): 180°F

- Speed Control: VFD

- Flow: Supply, Exhaust

- Filtration: Unfiltered

PLC

Centrifugal plenum blower, belt or direct drive, airfoil wheel

Recommended Products

Accessories & Vari-Flow Controls