LEU

Low Profile Aluminum Propeller Upblast Roof Exhaust Fan

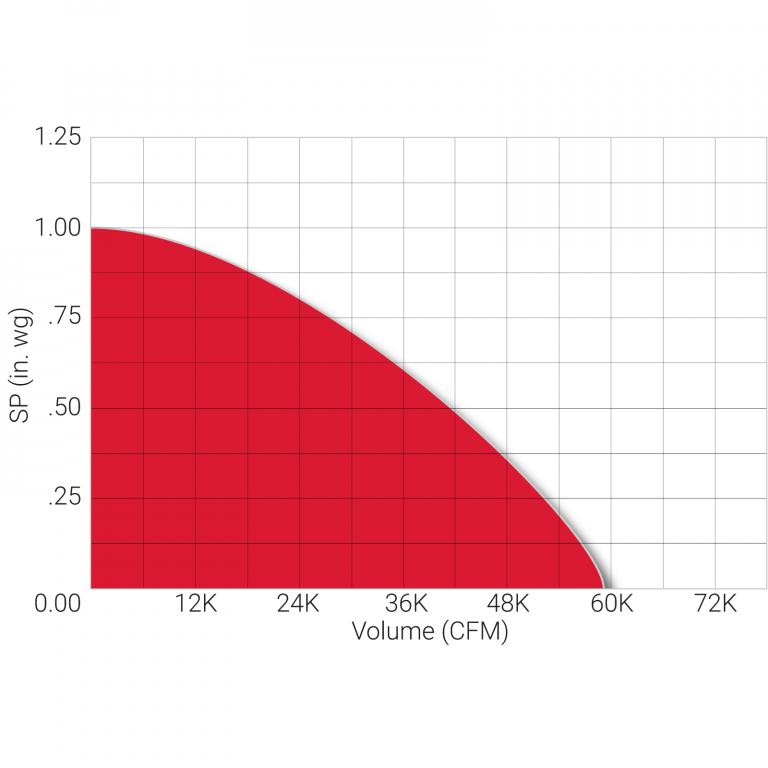

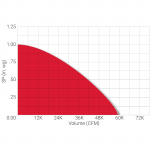

Extruded aluminum propeller, axial unit. Upblast, belt or direct drive, curb mount, low profile unit with butterfly damper doors. Commonly used in a variety of commercial to light industrial exhaust applications at higher flows with lower static pressures compared to traditional centrifugal applications.

Features

- Welded structural steel pipe power assembly

- Welded curb cap corners

- Lifting lugs

- Integral butterfly dampers

- Cast regreasble bearings

- Direct direct available upon request

Construction

- Housing Material: Steel

- Finish: Lorenized ™

- Ventilator Type: Fan

- Impeller: Axial

- Bearings: L-50, over 200,000 hours

Configuration

- Mounting: Roof (Curb Mount)

- Drive Type: Belt Drive

- Motor: AC

- Max Operating Temp (Standard Construction): 180°F

- Speed Control: SimpliDrive

- Flow: Exhaust

LEU

Propeller axial, upblast, belt or direct drive, curb mount, low profile

Recommended Products

Accessories & Vari-Flow Controls