VA

Aluminum Propeller Vaneaxial Fan

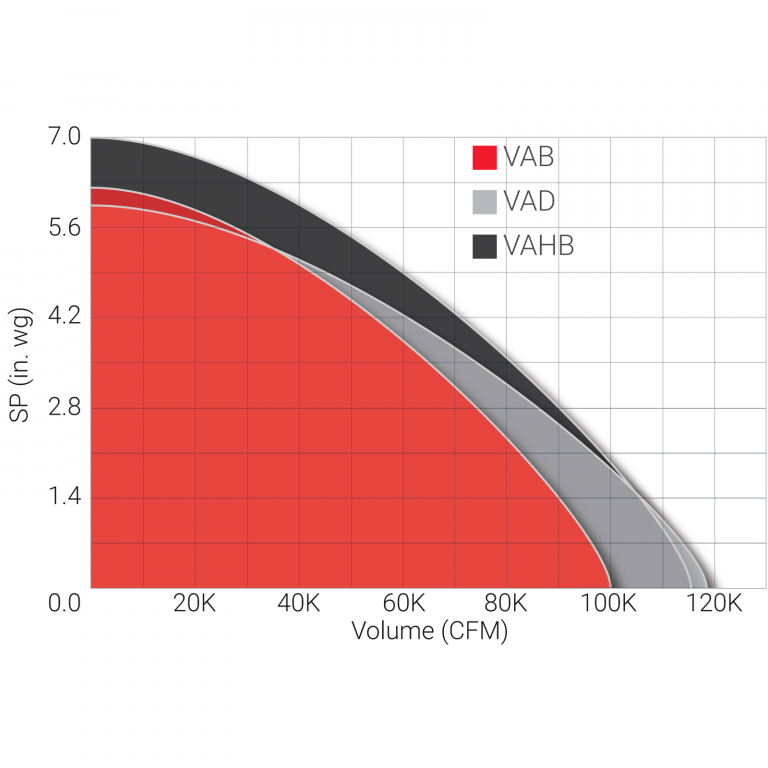

Fixed pitch cast aluminum propeller, vane axial unit. Belt or direct drive, duct mount unit with integral straighten vane section. Commonly used in a variety of industrial exhaust applications at higher flows and higher static pressures. Available in standard and heavy-duty construction based on static pressure and horsepower.

Features

- Fully welded housing

- Cast regreasable bearings

- Pre-punched flange for duct connection

Construction

- Housing Material: Steel

- Finish: Lorenized ™

- Ventilator Type: Fan

- Impeller: Axial

- Bearings: L-50, 200,000 hours

Configuration

- Mounting: Roof (Curb Mount), Roof (Rail Mount), Ceiling/Suspended, Duct Mounted/Inline, Wall, Floor

- Drive Type: Direct Drive, Belt Drive

- Motor: AC, PM

- Max Operating Temp (Standard Construction): 180°F

- Speed Control: VFD, Vari-Flow, SimpliDrive

- Flow: Supply, Exhaust

- Filtration: Unfiltered

VA

Vane axial, in-line, belt or direct drive, duct mount

Recommended Products

Accessories & Vari-Flow Controls