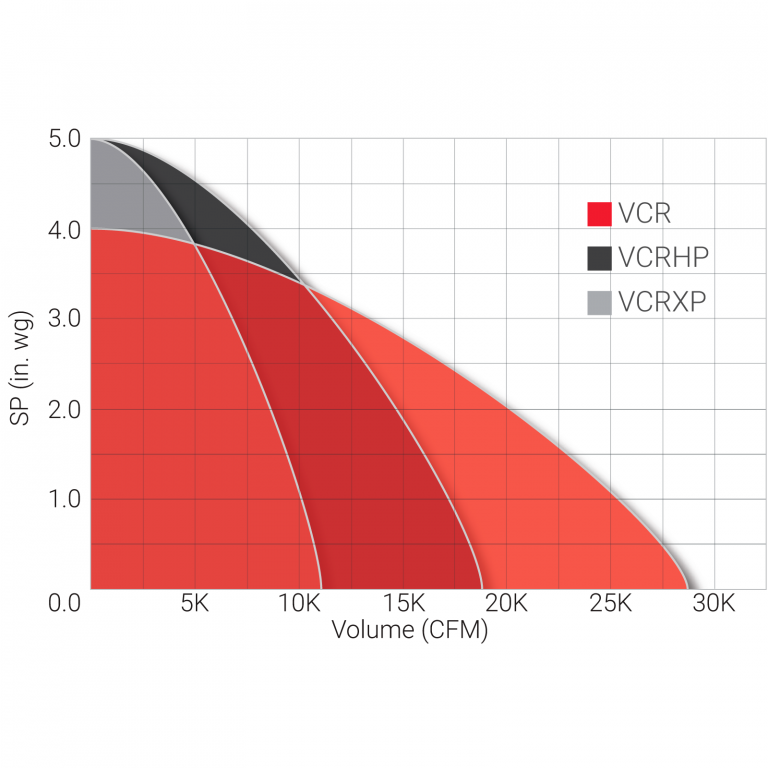

VCR

Upblast Centrifugal Resturant / Grease Exhaust Fan

Spun aluminum centrifugal roof exhauster. Upblast, belt or direct drive, curb mount. An economical choice for commercial kitchen exhaust. UL Listed Restaurant Exhaust unit. Available with optional hurricane (NOA) and seismic (OSHPD) certification.

Features

- One piece, leak resistant bottom spinning

- Lifting lugs

- Cast regreasable bearings (Belt Drive)

- Welded curb cap corners

- Easy, no tools required motor access

Construction

- Housing Material: Aluminum

- Finish: Mill

- Ventilator Type: Fan

- Impeller: Centrifugal

- Bearings: L-50, over 200,000 hours

Configuration

- Mounting: Roof (Curb Mount)

- Drive Type: Direct Drive, Belt Drive

- Motor: AC, PM, EC

- Max Operating Temp (Standard Construction): 300°F

- Speed Control: FSC, VFD, Vari-Flow, SimpliDrive

- Flow: Exhaust

VCR

Centrifugal exhaust, upblast, belt or direct drive, curb mount, UL Restaurant exhaust

Recommended Products

Accessories & Vari-Flow Controls