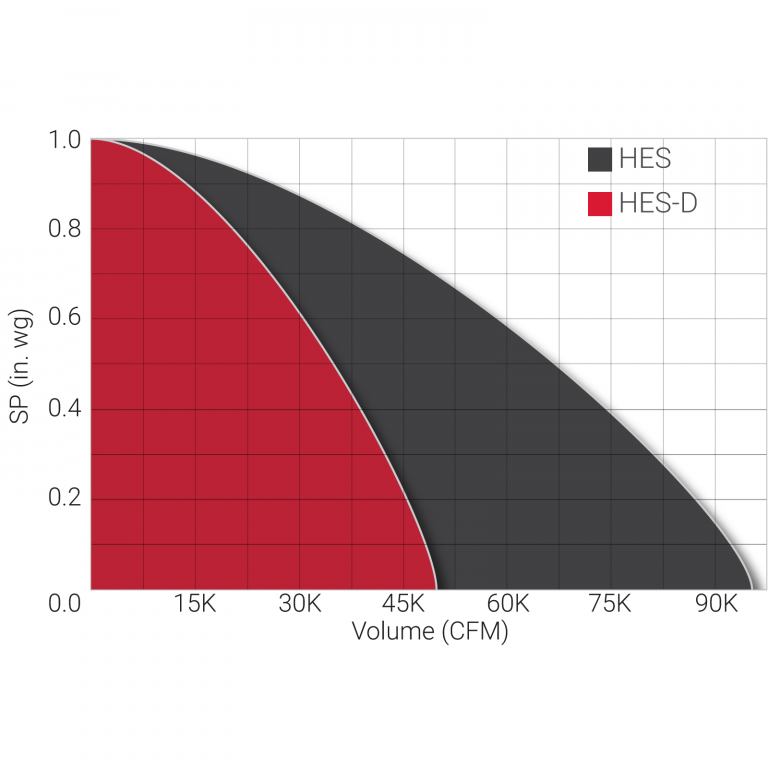

HES

Roof Mounted Hooded Propeller Supply Fan - Aluminum Propeller

Extruded aluminum propeller axial, supply unit. Belt or direct drive, curb mount, hood style unit. Commonly used in a variety of commercial to industrial applications to supply air against low resistance. Unit’s design meet ASHRAE 62.1 guidelines for intake hoods.

Features

- Welded base assembly with structural pipe power assembly

- Welded curb cap corners

- Galvanized hood with motor access

- Cast regreasable bearings (Belt Drive)

- Optional spark resistant construction available for direct drive units

Construction

- Housing Material: Steel

- Finish: Lorenized ™

- Ventilator Type: Fan

- Impeller: Axial

- Bearings: L-50, over 200,000 hours

Configuration

- Mounting: Roof (Curb Mount)

- Drive Type: Belt Drive

- Motor: AC

- Max Operating Temp (Standard Construction): 180°F

- Speed Control: VFD, Vari-Flow, SimpliDrive

- Flow: Supply

- Filtration: Unfiltered

HES

Propeller axial, roof supply unit, belt or direct drive, curb mount, hooded

Recommended Products

HEF

Propeller axial, roof filtered supply unit, belt or direct drive, curb mount, hooded

View ProductAccessories & Vari-Flow Controls